|

| How to start with the Kanban? |

Kanban has its roots in Toyota manufactories where the whole lean concept was born. The word Kanban exactly means signboard in Japanese, and it was a piece of paper on which there was information written, like what to produce, how many pieces and due to which date. It is an implementation of Just In Time manufacturing process, where elements are provided when needed.

This approach is also known as „pull“ system. Supplying is determined by the current demands of the customer, in contrast to the „push“ systems, where demand is forecasted. The latter means that goods are produced and stored in warehouses.

But there are at least two disadvantages of up-front creating.

- The first one is storage, which does not come cheap.

- Keeping goods in warehouses is not a cost effective approach. The second is that the future is not entirely predictable.

All

kind of bad things can happen and if demand for goods changes, you will

be left with arehouses full of items and no financial liquidity. Kanban

reduces those drawbacks, that is why it is spreading widely.

There are four Kanban principles, which you need to know before implementing Kanban solutions in your area. Let's take a look at them closer.

Work visualisation

There is a known sentence that a picture is worth more than a thousand words. And it is completely true, as our brains are processing images a lot faster than a text. That is why every implementation of Kanban uses a visualization of the process.

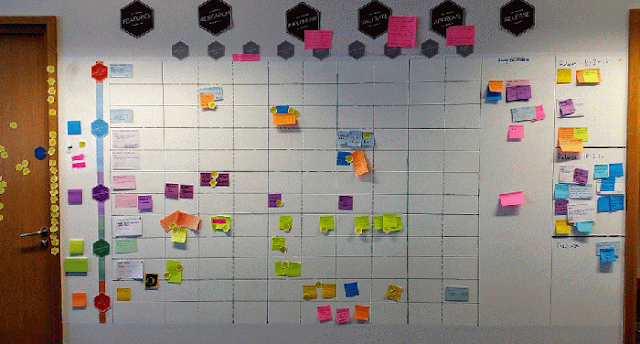

Usually, it is a Kanban board, a simple table where columns represent states of a task while rows represent tasks themselves.

By visualizing the workflow, you make it more transparent for every team member so the communication raises. Also, at one glance, you can check where there are bottlenecks or blockers and you can apply some improvements instantly.

Limiting Work In Progress (WIP)

Setting a limit for items which are currently being processed is crucial for reducing a time which is needed to make task done (a lead time). Limits can differ between each state in the Kanban Process.

Let’s take a real-life example, where there are two persons washing dishes, and one person is cleaning and the second is wiping them out. When the first person is faster than the second, after some time, we will have a big amount of washed but not dried dishes.

Despite the fast washer, we still do not have dishes ready to use. So, there is no need to wash those dishes so fast, as washed but not wiped dishes are a waste. It may turn out that you only need ten plates at the moment to be ready, but you already have twenty of them in a queue.

Focusing on flow

The smooth flow through the Kanban process is the key value of this method. Because of this, you should focus on the flow, collect metrics and continuously keep an eye on it. Deep understanding of your current flow will help you find bottlenecks, blockers and predict problems in the future.

Continuous Improvement

This one is common to all Agile methodologies, as all of them are empirical and need a constant improvement. As your Kanban goes on and you gather some info about the flow you can start to tweak it. For example Work In Progress limit set once, will not be there forever.

The whole environment all around changes and you need to adjust your process management to it. That is why WIP can change when it is no longer valid to the current conditions.

When starting with Kanban, it is advised, to begin with, what you already have. Those simple steps will show you how to start.

Step 1. Visualize your workflow

Examine what stages the task have to pass through to be done. Important here is to map steps as they actually are, not what you wish them to be in the future. write them down in the proper order and consult with others if you haven’t missed something. You can arrange them in columns, with the flow from left to right.

Step 2. Visualize your current work

Once you have all the stages described, put all your current tasks there. Each item should fit the stage, in which it is at the moment of putting. After this step, all your work should be already visible, and you have clarity about how much work there is currently in each stage. It is enough for you to start thinking about your process.

Step 3. Think about the flow

Take the whole team in front of the visualization from step 1 and 2 and think together about your current flow. When it comes to columns, think which one is redundant and if there are any missing stages, which should be added. Check also, how many tasks there are in each column. you can even write the number of them in each section, to see it more clearly. It will help you to see the bottlenecks and introduce the step 4.

Step 4. Setting WIPs

As you remember the dish washing example above, where there are columns with a big number of tasks waiting to be pulled to another stage, it means this column needs a WIP limiting. Set the number which seems reasonable to you and check how the flow changes within next couple of days. Then adjust this number if necessary.

Step 5. Improve

As I mentioned before, Kanban is an empirical process, which means you have to tweak it to your needs. By visualizing and gathering data about the flow, you learn what works for you and what not. With this knowledge, you can change the process to increase your productivity and shorten lead times.

This article is a remarkably short introduction to the topic but gives you some information about how to start your journey with the Kanban. Once you start, you can go deeper with your knowledge by reading proper books, watching presentations and discuss issues with other Kanban fans. As this method is effective, it is very popular, and there is no problem to find the answer on any of your future questions.Sampe record ebinar regrrding ussage of agile and kanban in aec

The Author : Tekin Guvercin

About :

Experienced Chief Executive Officer with a demonstrated history of working in the management consulting industry.

Skilled in Business Process, Sales Management, Project Portfolio Management, Primavera P6, and Contract Management.

Strong business development professional with a Structural Design focused in Civil Engineer, M. Sc. from Atatürk Üniversitesi.

Post a Comment