|

| Cost estimation template for software development |

Cost estimation template for software development

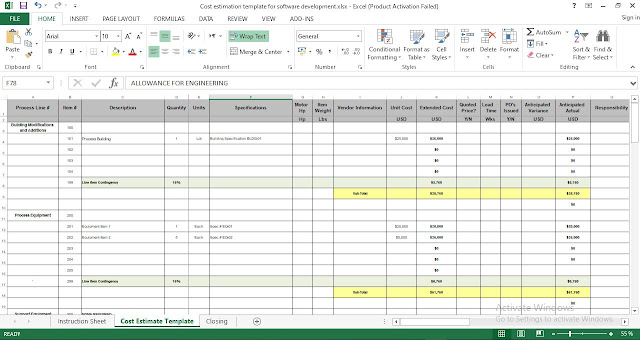

EFI Group has developed a Cost Estimating Template to ensure consistent application of the Best Practice Techniques from our experience. This template includes both mandatory and open line items for Project Managers to use when estimating project. EFI Group uses this same template for every phase of project development from Preliminary Engineering through Cost Tracking for Project Implementation.

Instructions for using Cost estimation template for software development

1-Site Preparation, Buildings, Structures and Foundations: List all known installation items that are part of Civil, Structural and Architectural design (CSA Design) for the project. Most often we will include BOTH the installation costs and the purchased material costs in this section of the spreadsheet.

2-Applies to ALL Direct Cost Sections: The Line Item Contingency (LOC) is a special feature of all direct cost items, sections 100 through 800. The purpose of LOC is to mitigate risk for price increases on a specific line Item. As a starting point, we normally show 15% as LOC. As more cost information is known within each project group, we will lower the percentage.

3-Process Equipment (purchase ONLY): All equipment that is used in the process is listed here. Sometimes for large projects, we will include a separate equipment list spreadsheet and transfer a summary of costs here.

4-Support Equipment (Purchase ONLY): Support equipment is often overlooked when estimating projects. We include a separate section to capture costs for this equipment. Typical examples of support equipment include: air compressors, maintenance cranes, special tools, mobile equipment, etc.

5-Installation of Mechanical Equipment: Cost estimates for all mechanical construction costs are detailed in this section. This includes the installation of process and support equipment. Also included is all piping associated with the project.

6-Electrical Power Supply Equipment (Purchase ONLY): Line items associated with power supply equipment are listed here including: substations, transformers, MCC's, power panels, etc. Sometimes light fixtures are also included here, but can also be shown as a single installation Item in Section 700.

7-Controls Related Equipment (Purchase ONLY): Controls related equipment are shown in this section including: PLC's, HMI's, control panels, instrumentation, etc. Note: Often a separate instrumentation list is prepared, transferring the total costs for the instrumentation package onto a single line item on the Cost Estimate template.

8-Electrical Power & Controls Installation: Contractor labor and tools associated with the installation of power systems and controls are listed here. Installation bulk items (conduct, wire, local receptacles, switches, etc.) are grouped in this section. We would normally include here all bulk items that are part of the Construction Scope of Work.

9-Miscellaneous: We use the "Miscellaneous" section to capture additional costs associated with direct costs that are not specifically mentioned in the sections above. See the template for the basic listing. The Project Manager can also include other items that are important to their project in this line item.

10-Indirect Costs: Indirect Cost are project costs that are not part of a fixed asset. Listed on the Cost Estimating Template are the Indirect Costs that we typically include on projects.

11-Final Project Contingency: Final Project Contingency is for a totally different purpose than Line Item Contingency. During the course of design or construction, NEW information and cost items arise that were not part of the original budget. Including Final Project Contingency mitigates the risk of cost items that WERE NOT identified during the original project planning and preliminary engineering. Typically, we will begin with 25% early in preliminary engineering and gradually reduce through the capital cost development activities. The lowest Final Project Contingency is 10%.

Download also:

Post a Comment